This gearmotor is a miniature (0.94" x 0.39" x 0.47"), high-quality, high-power motor with

100:1 metal gearbox, similar to Sanyo's popular 12 mm gearmotors. These units have a 0.365"-long, 3 mm-diameter D-shaped output shaft.

Key specs at 6 V: 320 RPM and 80 mA free-run, 25 oz-in (1.8 kg-cm) and 1.6 A stall.

Overview

These tiny, high-quality motors are intended for use at 6 V, though in general, these kinds of motors can run at voltages above and below this nominal voltage, so they should comfortably operate in the 3 - 9 V range (rotation can start at voltages as low as 0.5 V). Lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor. The micro metal gearmotors are available in a wide range of gear ratios' Âfrom 5:1 up to 1000:1 Âand offer a choice between two different motors: high-power (HP) and standard. With the exception of the 1000:1 gear ratio versions, all of the micro metal gearmotors have the same physical dimensions, so one version can be easily swapped for another if your design requirements change. Please see the micro metal gearmotor comparison table for detailed specifications of all our micro metal gearmotors. This dynamically-sortable table can help you find the gearmotor that offers the best blend of speed, torque, and current-draw for your particular application.

Some versions of the gearmotors are sold with an additional 1mm-diameter output shaft that protrudes from the rear of the motor. This 4.5mm-long rear shaft rotates at the same speed as the input to the gearbox and offers a way to add a custom-built encoder to provide motor speed or position feedback.

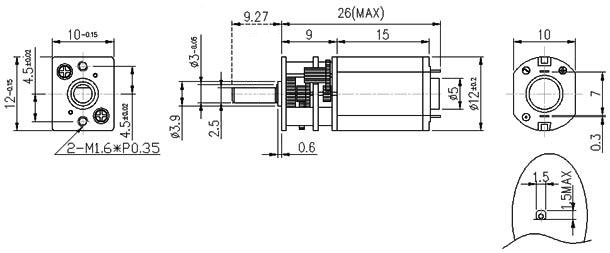

Gearmotor Dimensions

|

| Micro metal gearmotor dimensions (units in mm). |

The gearbox has a long (0.365" or 9.27 mm), 3 mm-diameter D-shaped metal output shaft, and the brass faceplate has two mounting holes threaded for M1.6 screws (1.6 mm diameter, 0.35 mm thread pitch). It weighs approximately 0.35 oz (10 g).

Motor Accessories

|

| Black Pololu 70 x Â8mm wheel on a Pololu micro metal gearmotor. |

|

|

| Black Pololu 90 x 10mm wheel on a Pololu micro metal gearmotor. |

|

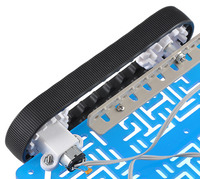

|

| Pololu 30T track set with drive sprocket mounted on a micro metal gearmotor to the left; idler sprocket is on the right. |

|

- Mounting Brackets: Our mounting bracket (also available in white) and extended mounting bracket are specifically designed to securely mount the gearmotor while enclosing the exposed gears. We recommend the extended mounting bracket for wheels with recessed hubs, such as the Pololu wheel 42 x Â19mm.

- Quadrature Encoder: We offer a quadrature encoder for this motor that works with our extended bracket and 42 x Â19mm wheel and provides feedback about wheel rotation (direction and speed). The encoder can be purchased as an individual unit or as part of an encoder set that includes two encoders, a pair of extended brackets, and a pair of 42 x 19mm wheels' Âjust pick the particular micro metal gearmotor that best suits your application and you have a solution for closed-loop motor control.

- Motor Controllers: We have a number of motor controllers that make it easy to drive these micro metal gearmotors, including our qik 2s9v1 dual serial motor controller and our programmable Baby Orangutan and Orangutan SVP robot controllers. The inexpensive qik 2s9v1 allows variable speed and direction control of two small, brushed DC motors using a simple serial interface; the Orangutans combine a programmable Atmel AVR microcontroller and dual motor driver all in a single package and make interfacing with the motor drivers simple when you use our Pololu AVR library. All of the above controllers use the TB6612FNG dual motor driver, for which we also offer a simple carrier board.

Selecting the Right Gearmotor

We offer a wide selection of metal gearmotors that offer different combinations of speed and torque. Our metal gearmotor comparison table can help you find the motor that best meets your project's requirements.

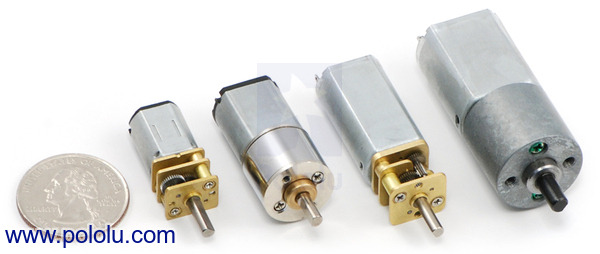

|

| Some of the Pololu metal gearmotors. |

No recommended products at the moment.

No recommended products at the moment.